|||

1. Factors that interfere in mycotoxin production

Mycotoxins are toxic substances that result from secondary metabolism of several strains of filamentous fungi. They are organic compounds with low molecular weight and no immunogeneticity. In tropical and subtropical climates the fungi development is enhanced by factors such as excellent humidity and temperature conditions. Fungi grow and spread well in cereals, especially in peanut, corn, wheat, barley, sorghum and rice, in which they generally find a highly nutritious substrate for their development.

Fungi growth and mycotoxin production in cereals can occur in several development phases, maturation, harvest, transportation, processing or storage of grains and forages. That is why a reduction of cereal humidity through a drying process and a correct compacting and sealing in silage, are of fundamental importance to reduce contamination levels.

More than 400 mycotoxins, presently known, are produced by approximately one hundred fungi. The main mycotoxins can be divided into three groups: Aflatoxins, produced by fungi Aspergillus such as A. flavus and parasiticus; Ochratoxins, produced by Aspergillus ochraceus and several species of Penicillium; and Fusarium toxins, representing the main types the trichothecenes, zearalenone and fumonisins,

Mycotoxin production depends on a series of factors such as humidity, temperature, oxygen availability, fungi growth time, substrate composition, damage to the grains integrity caused by insects or mechanical/thermal factors, quantity of fungi inoculum, as well as the interaction/competition among fungi strains. Genetic characteristics represent a more decisive factor to the solution of the problem. This complex of factors shows that their control, as preventive measures, is more than often very difficult. As a result of wet weather conditions, Brazilian climate at harvest, do not favor grains drying, especially corn.

Other species, such as Aspergillus fumigatus, Byssochlamys nivea, Monascus spp., Penicillium roqueforti and Trichoderma spp. are adapted to the silage conditions and are generally identified in preserved feed. In this case, contamination by fungi can be present before or after the ensiling process.

Although they are exposed also when grazing, the feedlot feeding system submitted animals to a more vulnerable condition, especially bovine cattle, because practically all their feed is based on concentrate and conservated forages (silage, hay, haylage, etc). Concentrate have grains in their composition which are commonly contaminated with fungi and mycotoxins. Corn grains are a classic example, often found with high humidity, badly packed and more than often used even after fungi deterioration, presenting high levels of contamination.

Ensiling should be the ideal method to conserve forage or the grains contaminated by mycotoxins, because after the harvest the forage is stored in low anaerobic and pH conditions, an incompatible environment for the development of filamentous fungi. However, silage is potentially subject to aerobic deterioration, preferentially in peripheral areas of the silo. Filamentous fungi develop in high quantities when the silage remains in contact with the air for a long period of time. The protection against air infiltration during storage and the correct handling of the silo during the feed out process avoid the aerobic deterioration process, also inhibiting the spreading of microorganisms that produce mycotoxins.

The rupture of the plastic film that covers the silo, is usually due to animals stepping on it, or to excessive sun exposure that dry and crack it, exposing part of the ensiled mass.

For these reasons it is necessary to put in practice all the strategies to reduce oxygen penetration in the silo, avoiding its undesirable effects both in nutritional and hygienic issues, during storage or silage consumption.

On the other hand, some fungi are capable of producing mycotoxins in plants, even before ensiling. The plant in senescent stage allows this growth resulting in contamination of silage by mycotoxins, even when raised properly as agronomic management.

Therefore, before ensiling it is necessary to properly size the silo regarding daily demand, because if this step is neglected, silage is no longer an efficient option in food conservation because of problems related to losses and development of undesirable microorganisms.

2. General effects of mycotoxins in animal health

Besides direct losses of ensiled forage, the consequence of ingestion of spoiled silage reflects directly in the animal's performance. Cases of reproduction disorders, low weight gain, immunity depression, heterogeneous groups, are usually related to the presence of mycotoxins in silage. These intoxications become more and more frequent due to better observation and lower tolerance of animals with high potential yield.

When mycotoxins are ingested, the several effects are due to their different chemical structures, influenced by the fact of being ingested by different superior animal organisms and also by the variety of species, breed, gender, age, environmental factors, management, nutritional conditions and other chemical substances. Mycotoxicosis brings huge economical, sanitary and commercial losses, especially because of its anabolic, estrogenic, carcinogenic, mutagenic and teratogenic properties.

The major problem of mycotoxicosis are losses related to several organs and systems of animals, implying on the decrease of their productive performances.

Acute manifestations occur when individuals consume moderate to high doses of mycotoxins. Clinical signs can appear associated with a specific pathological state, depending on the ingested mycotoxin, the species susceptibility, individual organism conditions and the interaction or not with other factors. Injuries depend on each mycotoxin. However the most common are hepatitis, bleeding, nephritis, necrosis of digestive mucous membrane and death.

Chronic mycotoxicosis is the most frequent, occurring when there is an intake of moderate to low dosage. In these cases, the animal exhibit symptoms characterized by the reduction of reproduction efficiency, lower feed conversion, decrease of growth rate and weight gain. This state is only detected with special care or by an regular analysis program of mycotoxins present in feed. Clinical signs can also be confused with poor nutritional management, other diseases including those that come from this mycotoxicosis or with nutritional deficiencies.

3. Prevalence of mycotoxins in grains and feeds

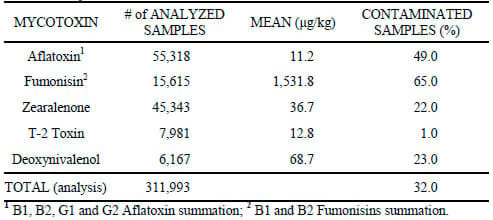

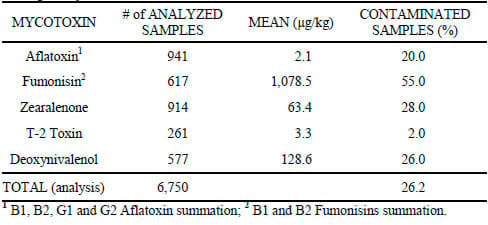

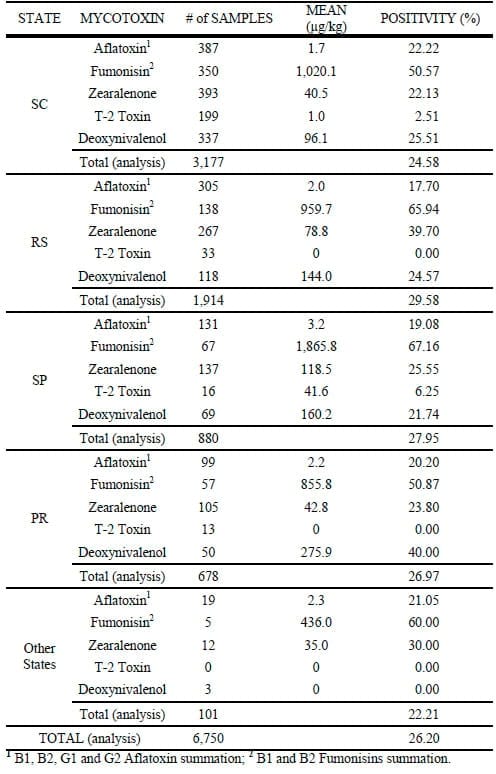

Results of mycotoxicologic analysis from the Laboratory of Mycotoxicologic Analysis (LAMIC) of the Federal University of Santa Maria, from 1986 to 2009, show the mean contamination by mycotoxins and the positivity of corn samples, where the aflatoxin, considered the most important group of mycotoxins, were detected in roughly half of the analyzed samples. On the other hand, toxins produced by Fusarium, fumonisins with 65% of prevalence, zearalenone with 22% and deoxynivalenol with 23%, are mycotoxins of high incidence in corn (Table 1). In Table 2 an average contamination by mycotoxins and the positivity of silage samples from all over Brazil is shown, illustrating that one fifth of the samples were contaminated by aflatoxins, over half were contaminated by fumonisins and more than one fourth by zearalenone and deoxynivalenol. When the silage samples in Table 2 are divided according to their origin from different Brazilian states, 4 states demonstrated a larger number of analyzes, Paraná, Rio Grande do Sul, Santa Catarina and São Paulo (Table 3). The major prevalence of fumonisins was detected in the samples from the states of Rio Grande do Sul and São Paulo, with almost 65% of positive samples. The contamination by zearalenone was higher in the state of Rio Grande do Sul, with almost 40% positivity. In Paraná, the contamination by deoxynivalenol was larger than in the other states, with 40% of presence in the samples.

Table 1 – Mean concentration of mycotoxins and percentage of prevalence in samples of maize analyzed in LAMIC/UFSM from 1986 until June 2009.

Table 2 – Mean concentration of mycotoxins and percentage of prevalence in samples of silage analyzed in LAMIC/UFSM from 1986 until June 2009.

Table 3 – Mean concentration of mycotoxins and percentage of prevalence in samples of silage from different states in Brazil analyzed in LAMIC/UFSM from 1986 until June 2009.

4. Control and management of mycotoxins

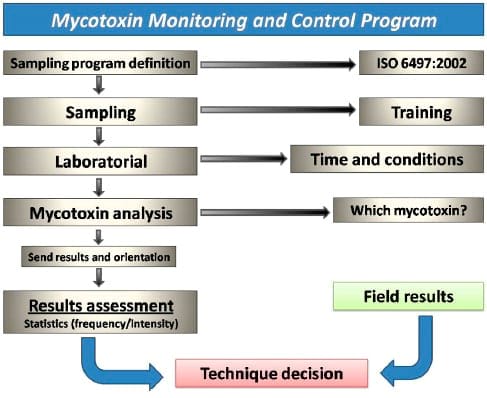

Control and management of mycotoxins involve a process which presents a series of critical activities, starting with the definition of a monitoring program. This implies on the definition of the sampling process, goes through several analyses and controlling points and ends in the decision-making. This should consider the reliability of the diet in which the risk of intoxication by mycotoxins can be minimized and the cost-benefit is precisely quantified, allowing the maximization of herd productivity.

4.1 Mycotoxin analysis program planning

A mycotoxin analysis program planning requires knowing the characteristics of mycotoxin distribution. Knowing the dynamics of mycotoxin distribution and how to interfere in decreasing the sampling risk are fundamental in a program.

The most practical way that was found to decrease the risk and offer a suitable balance between cost-benefit is showed in Figure 1.

Figura 1 – Mycotoxin monitoring and control program

4.1.1 Cereals sampling

The sampling program used in most industries assisted by LAMIC is recommended by the UE standard committee (Amtsblatt der Europäische Gemeinschaften N L 102/1, TEIL II, 1976 e Futtermittelrecht mit Typenliste fur Einzel - und Mischfuttermitteln, 1994), and later standardized by ISO 6497:2002. Technical adaptations to attend the dimensions of food processing industries, were made to always sample raw material after being grounded, allowing better feasibility and representativeness. Sample collection should be done when the material is moving and grounded, in pre established time intervals, depending on the amount processed daily. Therefore an animal feed factory that produces 100 tons per day, will do a minimum composite sample of 44.7 kg of grounded material, according to the equation 20xT , T being the number of tons produced. This material will be better collected if dynamically sampled through the "hole in the screw" system, which allows obtaining a constant sample of the previously grounded material flow during processing. A sample of at least 1 kg must be destined to laboratory analysis.

The sample should be sent to the laboratory as fast as possible, accommodated in a resistant package. For distant areas, the use of air transportation is recommended, in order to reach the lab no longer than 48 hours.

The analysis and mainly the definition of which mycotoxins should enter in a control program can only be defined knowing their prevalence in specific regions where grains are harvested. Because of the need in making fast decisions in agribusiness, it is recommended for the analysis to be made as soon as possible, obligating the analytical process to be also fast and precise.

In the result evaluation it is necessary first to establish confidence interval for the sampling system. The usual procedure starts with the collection of at least 2 samples per batch. The results are evaluated in their amplitude so that the number of samples to be analyzed is adjusted. After an initial period, it is possible to reduce the number of samples to one per day, depending on the total production and the contamination variability of the original substrate.

4.1.2 Silage sampling

Doing the total sampling of a silage silo can seem of great worth, however, to do so it would be necessary to rip the plastic film that covers it favoring the entrance of oxygen and consequent development of undesirable microorganisms. It is not so important to know the contamination by mycotoxins in the whole ensiled product, but to know the fractions that are being used and that are in contact with oxygen, which could be favoring the production of mycotoxins at a time. The accumulation of daily samples during a period represents the best way to trace the feed offered to the herd.

Another way to justify the sampling being made only in the open portion of the silo is that, generally in the ensiling process, the forage mass is disposed in layers, allowing the existance of slices of product, in which, the surface sampling is enough for the total silo representativity.

The method of sampling and shipping samples consists in:

In case the sample is not dried before sending to the laboratory, it should be stored in a plastic bag, in a way that it is well compacted inside the package, which should be hermetically sealed. Sending the sample in a thermal refrigerated or vacuum sealed box, suppresses the fungi growth and mycotoxin production that may occur during the sample shipping and receiving period.

4.2 Mycotoxin Diagnosis

Nowadays the most specific, precise and reliable methodologies are obtained with the use of chemical processes. These procedures can be directed to Thin Layer Chromatography (TLC) as well as to High Performance Liquid Chromatography (HPLC). With the emergence of HPLC linked to the detection of Mass spectrometry (L/CMS and LC/MSMS) besides Gas chromatography-mass spectrometry (GC/MS), the diagnosis systems tend to be faster and more precise. The immunoassay tests can be used for selection and, in exceptional cases, for semi quantification. The use of chemical evaluations are accepted in international methodologies and recommended for the diagnosis of mycotoxins. The use of extraction in the solid phase brings progress, especially in standardizing and automation of mycotoxic analysis.

The analysis system used in "on line" monitoring uses the HPLC joined with automated extraction, purification and derivation methodologies, as well as LC/MSMS systems, decreasing the use of laboratory technicians labor force, besides minimizing analytic errors and providing a fast response in diagnosis.

4.3 Decrease of mycotoxin toxic effect using Anti-Mycotoxin Additive (AMA)

Once mycotoxins are formed, the inhibition of the fungi growth will not imply on their concentration decrease. A frequently used method to control mycotoxicosis is the use of material nutritionally inherent to the animal's diet, in order to decrease the absorption of mycotoxis in the gastrointestinal tract. These substances were called mycotoxin adsorbent and are now generically called Anti-Mycotoxin Additives (AMA).

In the Brazilian market, where approximately 100 AAMs for poultry and swine were evaluated, only about 30% presented effectiveness. Due to the fact that most of the product did not attend the demands for the use as AAM, the uncertainty of how much and how to use a truly effective product still remains. The answer comes with constant monitoring of the feed factory.

In a way, all diets for a pre initial phase should have inserted in their formulation an AAM. Diets for the other phases, must consider the Mycotoxin Risk (MR) before inserting AMA. This index considers the interaction between mean contamination of analyzed samples and mean prevalence of each mycotoxin in these samples, which is used as reference for decision making regarding the use or not of AAM.

5. Conclusion and Recommendations

The presence of mycotoxins in an animal's diet can determine significant losses in the production system. The considerable presence of mycotoxins in the main components of the diet determines the need to adopt a continuous control program which can be based on the use of AMA (adsorbents). To adopt control measures it is necessary to know the prevailing contamination precisely, making it indispensable the implementation of a monitoring program of silages and feed destined to animal intake.

The future control of the mycotoxin problem, in livestock economy, depends on the implementation of adequate policies in agricultural management extent, as well as production and storage systems. Only policies in these areas will bring solid and long lasting economical results for livestock industry.

References

AMARAL, R. C.; BERNARDES, T. F. Presença de micotoxinas em silagens: Efeitos na nutrição de ruminantes. In: Milkpoint. 2008. Disponível em: <http://www.beefpoint.com.br/presenca-de-micotoxinas-em-silagens-efeitos-nanutricao- de-ruminantes_noticia_50491_60_160_.aspx>. Acesso em: 18 jun. 2009.

AMARAL, R. C.; BERNARDES, T. F. Os fungos e a contaminação com micotoxinas em alimentos de uso zootécnico: parte 2. In: Milkpoint. 2007. Disponível em: <http://www.beefpoint.com.br/default.asp?noticiaID=34611&actA=7&areaID=60& secaoID=160 >. Acesso em: 18 jun. 2009.

AMTSBLATT DER EUROPÄISCHE GEMEINSCHAFTEN. NL 102/1, Erste Richtlinie der Kommission zur Feststellung gemeinschaftlicher Probenahmeverfahren für die amtliche Untersuchung von Futtermitteln (76/371/EWG) Teil II, 1. 03.1976. 35p.

DEMARCHI, J. J. A. A. Ocorrência de fungos em silagens e produtos armazenados. Milkpoint / Beefpoint - O Ponto de Encontro da Pecuária de Leite/Corte - Radares Técnicos - Conservação de Forragens, Piracicaba - SP, P. 1 - 3, 14 set. 2001.

HAYES, J.R. & CAMPBELL, T.C. Contaminants. In: CASARETT, L.S. (Ed.) Toxicology: The Basic Science of Poisons. New York: McMilliams, 1986, p.771- 800.

ISO 6497:2002. Animal feeding stuffs sampling. 19p. 2002.

MALLMANN, C. A. et al. Critérios para seleção de um bom sequestrante para micotoxinas. Conferência APINCO 2006 de Ciência e Tecnologia Avícolas. Anais..., p. 213-224. 2006.

MALLMANN, C. A; DILKIN, P. Micotoxinas e Micotoxicoses em Suínos. Santa Maria: Sociedade Vicente Pallotti, 2007. 240 p.

PINTO, V.E.F. & VAAMONDE, G. Hongos productores de micotoxinas en alimentos. Rev. Arg. Microb., Buenos Aires, v.28, n.3, p.147-162, 1996.

WHITAKER, T. B.; DICKENS. J. W.; MONROE, R. J. Variability of aflatoxin test results. J. Am. Oil Chem. Soc. v. 49. p. 590, 1974.

WHITAKER, T. B.; DICKENS, J. W.; GIESBRECHT, F. G Testing animal feedstuffs for mycotoxins: Sampling, subsampling, and analysis, In: SMITH, J. E.; HENDERSON, R.S. Mycotoxins and Animal Foods. Cap. 8, p. 153, 1991.

Sumário de artigos disponíveis no site do LAMIC: http://www.lamic.ufsm.br/